Perusing another article here in CIO Magazine about 10 Big Data Trends Changing the Face of Business – and I’m struck by the ‘Data Trends’ being cited – they strike me mostly as nebulous and theoretical. One trend was listed as (and I’m paraphrasing – it’s not important enough to go back and look up) “We’re seeing lots more projects in production rather than skunkworks and we’re taking a much more pro-active…” At that point, the jargon detector in my head exploded and I couldn’t read any more.

After gathering up the pieces of my blown-up head and placing them back together (I live a highly cartoon-like existence these days) I tried to analyze exactly what was going on.

For one, when I think of a trend, I think of real world examples of Big Data or Business Intelligence – things that are trending up in the real world.

I remember a few years ago when we developed some BI tools for Food Manufacturers within our ERP suite.

Lots of private label manufacturers put together hundreds of different products, think frozen foods – and make them for dozens of accounts – regional supermarkets, restaurants, big box stores and so on. Due to different manpower requirements of different recipes, different costs of ingredients, different sales contracts, delivery and terms and all the rest – most manufacturers know they’re making money at the end of the month, but without fail, there are generally a few products or customers which are not so profitable. As we installed our ERP package and started tracking cost down to the product level, the production line level, the labor and materials going into each individual item – we began to see commonalities. Mostly, about 5%, on average, of the products produced were losing money. The other 95% were carrying the weight and profitable.

Now 5% may not seem like much, but when we told the CEO we could use BI to increase his profitable factory output by 5% – ears perked up. 5% of a few hundred million in annual production can often add up to real money. 5% more is the difference between next year’s growth targets being achieved or having to break ground on another factory or factory expansion project – which can also tie up a few hundred mil (not to mention the mess construction can make).

So we showed Food Manufacturers which products were costing them money to make. They could either raise prices to the customer, fire the customer and let a competitor lose money instead, or any of a number of other management decisions. We did it once – it was a success. We did it twice, it was a data set. We did it three times, and it was a trend.

So that was what I was looking for in the CIO article – and it was a fine article with wonderful Big Data industry sources – but just not the meal I was hungry for (have you ever noticed writing about food manufacturing just before lunchtime tends to produce eating metaphors?).

And granted, Big Data is somewhat an extension of Business Intelligence – some would say wholly different due to scope and size – better to let the techie guys argue the distinction versus difference.

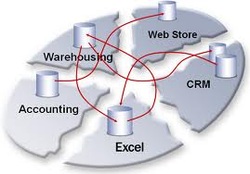

The one thing I do take from the Big Data article is that system integration is key – and I think this trend is again something that we saw major Fortune 500 companies embrace in years past, but now the midline companies really need to consider if they’re hoping to remain viable.

“System Integration?” you say.

Yes, system integration – the key to making all the software systems you have in place work harder and better. Is your CRM system fully integrated with Outlook so that you’re tracking email and phone communication with clients? When an employee updates HR, is Payroll and your AR system where you create expense checks both updated? The examples are numerous and specific to your business but you need to ask yourself, “When we input data twice, in two separate systems, what’s the cost of that double workload?”

You can generally make a case for cost benefit analysis on the labor saving side. Janeen in payroll inputs data into this system, which takes 6 minutes – then goes to that system and does the same update – which 10x a day, times 5 days a week times all the weeks in the year times Janeen’s hourly rate….

But the real advantage is productivity drag. When the employees have less ‘drag’ created by redundancy, productivity will generally increase far in excess of Janeen’s 6 minutes. Because each task has it’s start/stop time, each task has it’s management – putting it on the to-do list, crossing it off the to-do list, having the supervisor double check it’s done, the workflow interruption factor – on and on and on.

That’s the front end.

On the back end, is our business intelligence comparing data gathered in our Transportation Management System linked to the Financials? Are we collecting performance data in one system and tracking performance reporting in another? Why aren’t they ‘talking’ to one another?

It’s when we have data to combine our different software systems and measurement tools, we begin to be able to get a handle on these productivity drags and workload increases through automation.

Then we can spot real, actual trends within our businesses – and create real world case stories of how Big Data really performs.

So – question for you dear readers – what real life examples of Big Data trends have you seen in your business, in your customers businesses, or heard from your vendors/clients/partners?

Take a moment to drop us a line and let’s share a few trends – real life, actual Big Data solutions that work – you could end up on an upcoming Episode of our Podcast – or just click on the link above to visit the CIO magazine article – of course I’m not taking responsibility for any subsequent head-explosions.

You can reach us at Info@ProfitFromERP.com