I was recently asked to speak at the Arizona IT Women’s Network Breakfast on the topic of tablets/mobile devices in the workplace. Since I’m currently in a project with a firm that’s publishing a web app for Food Manufacturers to use tablets to increase food safety and sanitation, I thought I’d have something to offer in terms of how mobile devices in general are making inroads in the business environment. I also worked with a tablet based technology for food distributors – so a few more lessons learned there I could pass along. So off we go.

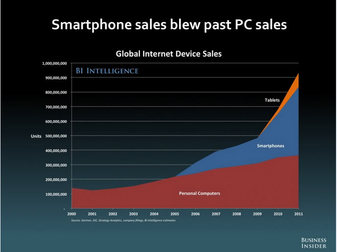

There’s no doubt mobile technology is big for business. Some have called it the post-pc era as tablets and smartphones outpace sales of desktop and laptop pc’s.

A few numbers from Techpinions Insiders – 350m pc’s were sold last year, compared to 1.7b smartphones. PC’s are replaced every 4 or 5 years (7 in my case) versus every 2 years for smartphones.

Some businesses are rapidly adopting mobile strategies with new apps and uses for tablets/phones – others are still wondering what it’s all about.

So if a mobile strategy has taken place at your workplace, it can almost seem like ‘why not? – that’s so simple, it’s obvious!’

But what if it hasn’t? Lots of companies seemingly have an attitude of ‘that just doesn’t work in our business model’ which can be true, until it’s not.

And thinking about my upcoming speech, with IT groups from many different companies, some mobile, some not, I thought if I could distill mobile strategy to the essence, then people would have a takeaway that could apply in a variety of settings – regardless of the specifics of different business models.

Or – even more importantly – when someone came in with a crazy idea to track poultry growth with mobile scanners and train turkeys to walk across scales daily – the IT folks could say – ummm, that might not work – it doesn’t have any of the underlying value drivers found in mobile/tablet technology adoption.

Back to the Future

As I was thinking about all this, I was reminded a similar breakfast meeting – it was the Austin Chapter of the American Marketing Association, about 1996 or early 1997.

Dell’s VP of Marketing at the time, who’s name escapes me, was speaking at this particular breakfast meeting.

He then asks if anyone had been on the brand new Dell website – a hand or two went up.

It seems this ‘new’ Dell website was designed to allow people to configure and purchase a new computer – to pick out the size of hard drive, monitor, memory – everything.

And then he made a statement I’ll always remember.

He said, “While it’s true that no one would ever buy a big ticket item like a computer on the internet – and we don’t expect them to – this new website lets them configure everything they want, so that when they do call our call center to place the order, they already know what they want, which has cut our talk time per order from 38 minutes to 12 minutes – meaning we now need half as many people in the phone room taking orders.”

And that was a significant cost reduction for Dell at the time.

Of course you know how history turned out – Dell would eventually sell a computer on the internet – – – plus a few more – and 6 months later Dell would be doing about a million dollars a day in internet sales and was one of the leaders in changing how we buy everything on the internet.

The point is, Dell lowered the transaction costs of selling a computer – instead of a Dell employee helping a customer decide how to configure their new pc, the customer did that themselves – saving labor time for Dell in the beginning, and eventually cutting out the phone operator all together. This would have been accomplishment enough to justify the web technology – but secondary benefits also kicked in – according to Wikipedia, Dell attracted the most tech savvy customers in the market who valued the opportunity to configure their own pc’s and Dell’s market share skyrocketed.

Today’s mobile and tablet technology – at least the effective deployments of mobile and tablets – are doing the same – lowering transaction costs in the short run, and often showing secondary benefits that no one imagined in the long run.

If you’ve ever been in an Apple Store, you know there’s no cash registers or check out lines. You simply walk up to any associate and they scan your purchase on an iPhone, swipe your credit card, email you the receipt and you’re on your way. Great use for mobile technology – and it’s also catching on in other retail locations such as Nordstrom’s, AT&T, J.C. Penny, and Urban Outfitters to name a few.

This cuts transaction costs because Apple doesn’t need cash registers and checkout staff – – but now Apple takes it a step further. After you download the Apple Store app to your iPhone, you don’t even need to find an associate – you pick up whatever you want to buy, scan the barcode yourself, pay with your credit card and email the receipt to yourself. I have no idea how self-checkout will affect shrinkage and shoplifting rates, I do know I can get in and out of the Apple store in record time.

The basic premise for any business is still the same – take a transaction – any transaction – and offload the transactional costs from your side of the balance sheet onto the customer side of the ledger – and in the process, empower the customer with more control, more choice, and exactly what she is looking for in less time.

But it’s not always a pure cost equation, mobile technology can also work by driving revenue.

In Food Distribution, the food service business provides food items to restaurants, catering companies, hospital cafeterias, deli and convenience stores.

The recent trend has been to covert the ordering process to mobile tablets.

Previously, a salesperson would visit the restaurant or store and sit down with the purchasing agent, chef or owner and check off quantities on a paper list – then sometime later, fax this 8 page list back to the office where someone would key it into the sales software to make the next truck route out to the customer.

Now, you give the customer a tablet preloaded with everything he normally orders, and let him enter his own orders – which upload directly to the sales software without someone having to fax or re-key the information. Quicker, easier, saves time, tons of paper and cuts costs right? That’s just the primary benefit.

Here’s where it gets really good. Historically, the customer can only order food once a week, when the salesguy came by. Now, if the restaurant has forgotten to order something or gets a rush of extra orders on the fish dinner, they can place an additional order anytime, 24×7 – so sales are up.

But what about the former salesguy? Out of a job? Not at all, he’s still coming by once a week, only instead of spending that 20 minutes taking paper orders, he’s now showing the chef how this new, table-side flaming Bananas Foster dessert is driving up average check prices, attracting more dessert orders from the other diners watching these exciting flaming desserts being prepared right in the dining room – he’s helping the chef make more money every night (and buy additional products from the food service company.) Everyone wins – even the gym across the street when newly fattened diners sign up to work off the flaming Bananas Foster dessert.

Which brings us to Food Safety.

Food Manufacturers are under increased scrutiny – every day, the FDA issues warnings, recalls and letters regarding outbreaks of tainted food in one industry or another.

Partially, this is due to greater testing of our food supply than ever before, and awareness has also increased – years ago, you may have heard that your distant Uncle ‘got food poisoning’ from he wasn’t sure where, and was out of sorts for a day or two. Now, you hear stories in the news that 350 people were affected by tainted chicken at the local Chick’o’Buffet. Fortunately for most, food poisoning is only a discomfort for a day or two – but for some with compromised immune systems, an outbreak of Salmonella can be life-threatening.

So over the past few years, food manufacturers have taken great strides to track every ingredient they purchase, with software systems that can pinpoint every single can of pickled herring that used the Malabar Cracked Pepper that suddenly tested positive for bacterial contamination (it seems Malabar’s food standards aren’t what they once were.)

Food Suppliers have also developed electronic systems to pinpoint every loaf of bread that went through the defective white bread slicer that’s throwing off metal shavings.

However, when it comes to sanitation, washing out the machines and factories that supply our food, most of the records were kept on clipboards full of paper checklists. Wash a machine, check off the box, wipe down a counter, check off the box.

Then, at the end of the day, all this paper has to be filed and kept on hand in case of any future recalls or food inspections. So someone has to file it, someone has to look it up when the inspector is due to visit – and if you want to show trends or track effectiveness, someone has to get all that paper out and start entering data in spreadsheets.

So now there’s an app for that – tracking the cleaning and sanitation process. Instead of a clipboard, the cleaning crews are taking tablets out on the manufacturing floor. They’re still checking off a box every time they complete a task – but now we have a chance to give them more information. We can link to videos showing how to complete a cleaning task. We can show them diagrams and dis-assembly instructions for manufacturing lines that need to be broken down.

We can also track progress – huge manufacturing plants lose money every minute they’re idle – if we can take a look in the office and see the mixing line has just been cleaned and is ready to go, we can start that line immediately – instead of waiting til the crew gets back from that part of the plant.

We can now trend cleaning records and track testing levels. And pull reports whenever an inspector shows up.

So at this point, we’ve cut the transactional costs of keeping records of our cleaning and sanitation.

But the secondary process helps even more.

If a cleaning crew skips a step – alerts go out so a supervisor can find out in real time if something’s really been skipped or if a crew just forgot to record the activity. Previously, these skipped steps were caught in testing the product before it’s shipped – but when a batch tests bad from a skipped sanitation process, that’s thousands of dollars of milk down the drain or hundreds of pounds of beef in the dumpster.

So again, we see an immediate drop in transactional cost with the use of mobile technology, followed by an increasing value from the secondary features made possible in an automated environment.

In Summary

My thinking is, if you haven’t figured out a mobile application in your business, and it just doesn’t seem to fit – try the following.

- Examine the transactions in your business model

- Imagine whomever you’re transacting with is holding a sign that says “will work for information”

- Determine how you can provide them with more information in exchange for them taking control of the transaction

- Offload your transactional costs

- Now that you’ve automated the process with the app, what else is possible?

We’d love to publish the results of any mobile efforts you launch using this pre-design analysis – even if your analysis shows how you avoided a potential bad mobile development project.

Also – since Tuesday’s speech – a couple of articles I’ve come across related to mobile projects.

InfoWorld has an article about Mobile Apps versus Web Apps – both apply – here.

InfoWorld also promoted an article about Rolling out Mobile Apps – here.

For information on any of the technologies listed here contact gh@genehammons.com. (Except for the name of that VP Marketing from Dell back in 1996 – I just can’t remember that one, and I wasn’t taking notes on a tablet at the time and haven’t digitized my files that far back.)